Success story

VULKAN INOX: Classic industry fit for the future

Things are heating up at VULKAN INOX, and not just in the melting process. The specialist for blasting media is also really heating up on the topics of innovation and sustainability in order to be successful in the future as well.

Blasting media Made in Germany

The Ruhr region is known for its heavy industry, which has shaped the region and its people for many years. Even today, Hattingen is home to VULKAN INOX, a true hidden champion. The leading manufacturer of granulated blasting media has been producing stainless blasting media for the surface treatment of e.g. aluminium, non-ferrous metals, stainless steel, concrete and natural stones for more than 35 years.

CHRONITAL® and GRITTAL® are produced by melting down selected high-grade input materials and adding further alloying elements, such as chromium and nickel, in induction furnaces. Once the desired chemical analysis and the correct casting temperature of approx. 1500 – 1600°C have been reached, the molten stainless steel is atomised. This produces blasting media grains of different sizes (from 0.05 to 3 mm in diameter), which are cooled and collected. The resulting grains are either immediately sieved, fractionated and packed or, depending on the product, hardened again, crushed and then sent on their way. The blasting media from VULKAN INOX are sold worldwide – 80% of the turnover is generated abroad.

Success in the niche

VULKAN INOX proves that it is also possible to be internationally successful in a classic industrial environment. The hidden champion’s secret recipe includes an excellent knowledge base, committed employees, a strong financial partner and continuous development of innovative solutions for the surface technology of the future. For example, VULKAN INOX was the first company to develop a sharp-edged blasting media. “For our self-image as an agile medium-sized company, the continuous search for new innovative approaches is a central factor,” says Managing Director Marc Hidde. “For example, we are currently developing a new, innovative alloy with the support of the INDUS development bank.”

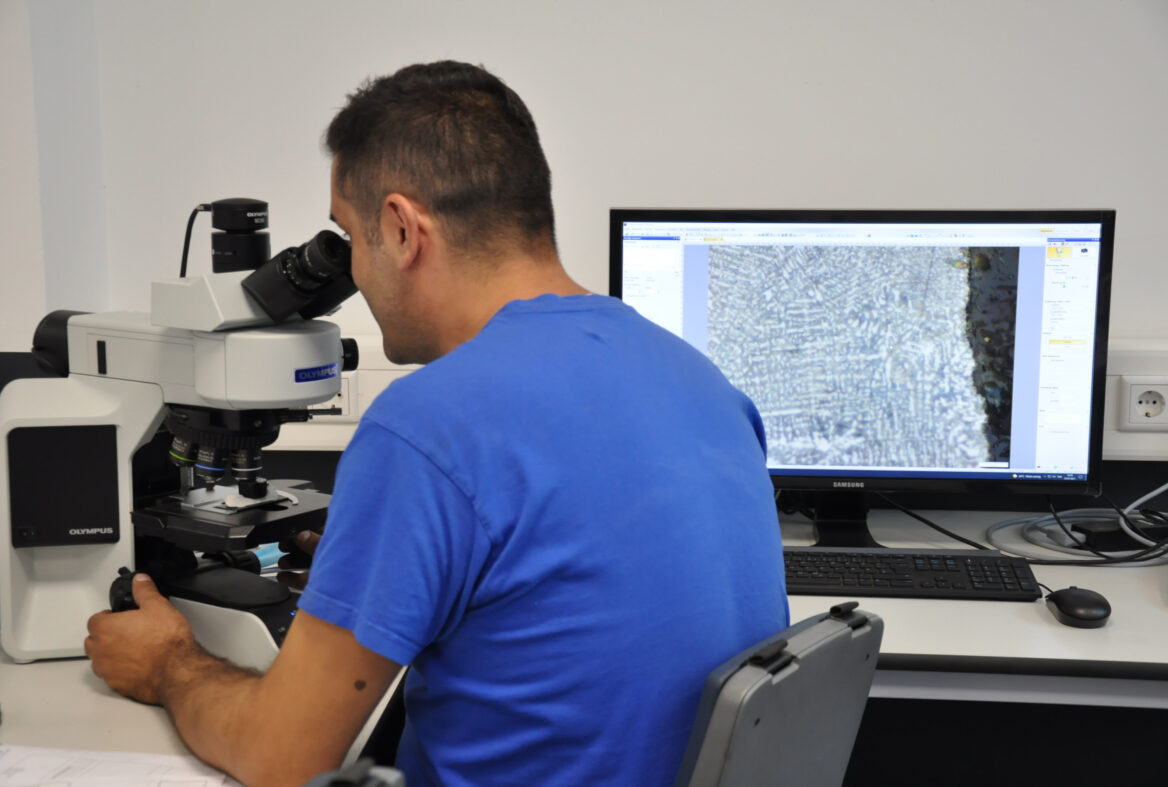

In addition to innovation projects, INDUS also promotes investments to optimise processes and working conditions, among other things. At VULKAN INOX, for example, a new 500-square-metre administrative building was built, complete with a modernised laboratory. This allows the high-quality standards to be implemented, as well as customer services, such as carrying out blasting and application tests to define the optimal blasting medium for the customer. In 2020, investments were made in a new, state-of-the-art dust extraction system that captures the flue gases from the induction furnaces. As a result, the quality of the purified air is considerably better than required by law.

Sustainable on many levels

In addition to innovations and investments, the topic of sustainability also plays a decisive, strategic role. Especially because metal processing is a very energy-intensive business, VULKAN INOX has established an environmental and energy management system. For example, it has been decided that from 1 January 2022 the electrical energy supply will be fed entirely from regenerative energy. The topic of resource conservation and recycling management is already of great importance to the company today – because compared to other materials, steel is sustainable per se and fully recyclable. In this way, metallic recyclable materials that are produced in other stages of the value chain can be recycled.

The produced blast media themselves are characterised by short blasting times and a very long service life and therefore count as reusable blast media. This is because, unlike ceramic or glass blasting media, they can be recycled several 100 times, depending on the product and application. The lower consumption and disposal quantity not only reduces the total operating costs, it also increases the quality of the blasting material and also protects the environment.

Further Information: www.vulkan-inox.de