Success story

Digitization during the Corona pandemic: IEF-WERNER is working on new, smart ways of working

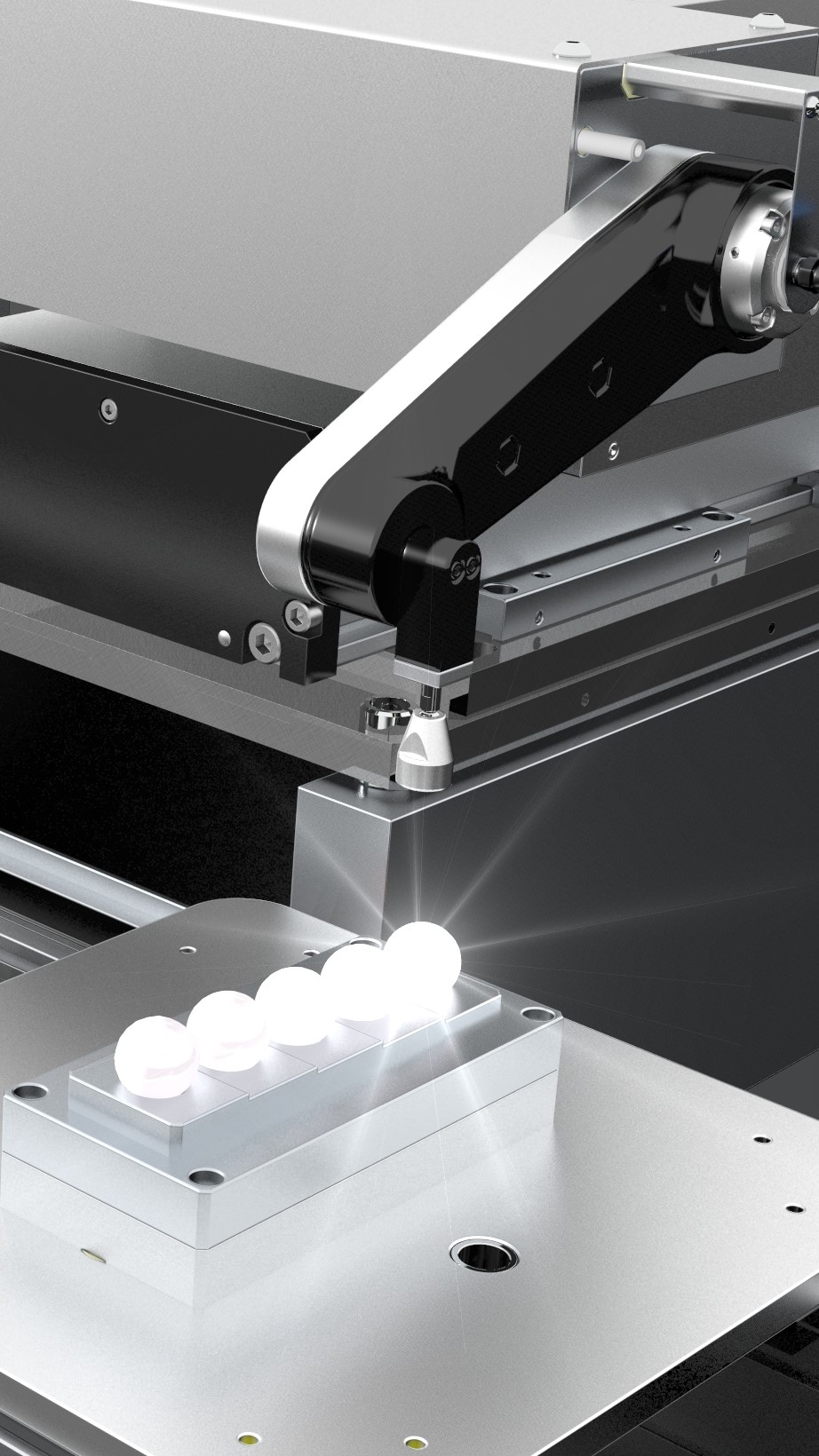

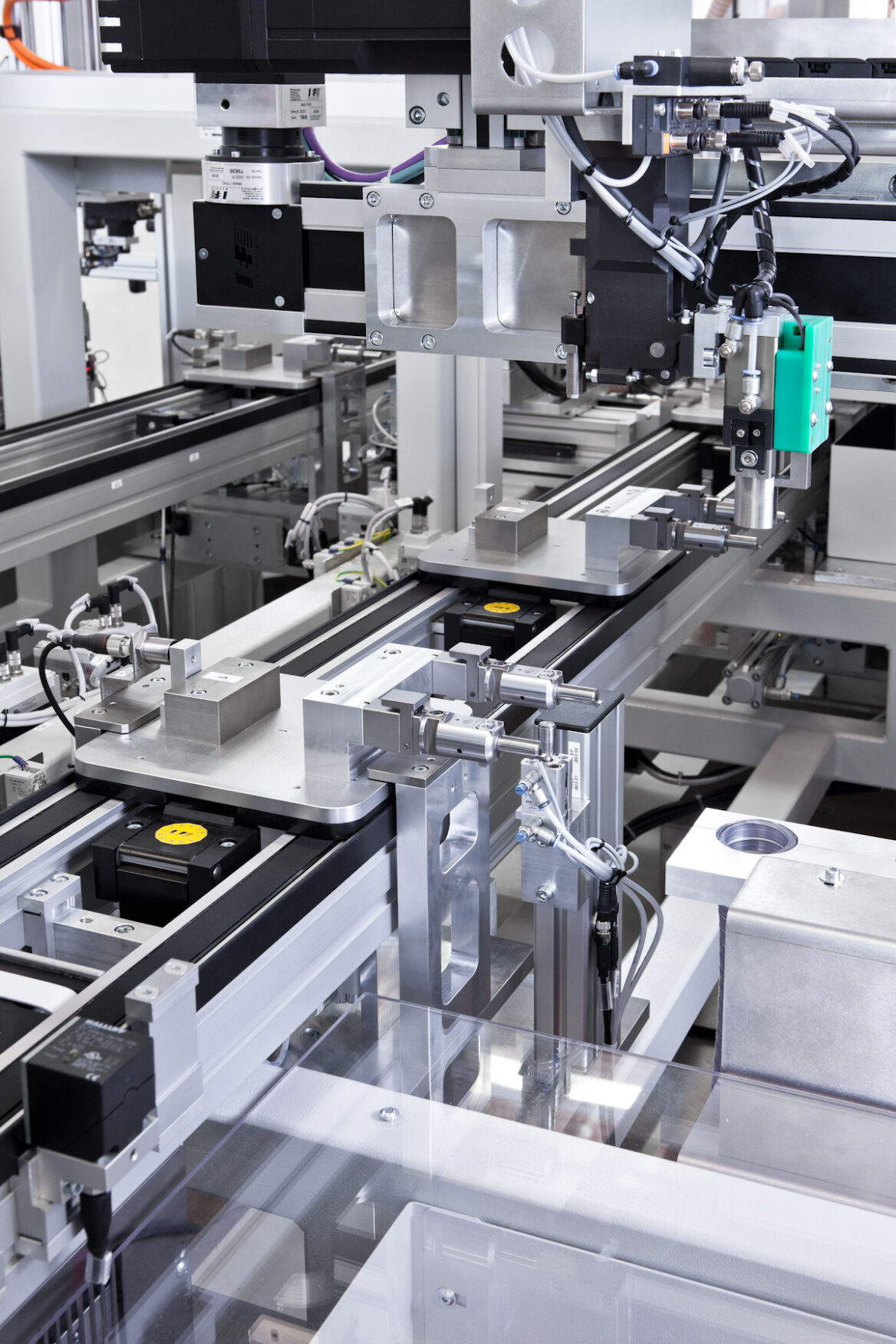

IEF-Werner develops and manufactures individual, specialized automation systems for a wide range of industries in the SME sector. Fully automated production lines or customized modules, the range of solutions is as broad as the customer base.

Predictive maintenance as the key

A major cost factor for all plants and customers, however, is the necessary maintenance of the equipment. Much more, the downtime of the machines, which costs cash during maintenance. This is where IEF-Werner comes in and tries to predict the condition of the machines for the customers as part of an INDUS development bank project. Predictive maintenance is the key word. Adapted to the respective plant or the respective modules, the solutions are customized, there is no patent solution. In concrete terms: with the help of sensors and mathematical models, data is analyzed during the running process, problems are detected at an early stage and reported by the machine. Optimally, a technician can intervene before a breakdown occurs. This prevents downtime and saves valuable resources. Even before the plant is built, it must be defined accordingly which data falls outside the norm and indicate a possible malfunction during operation. During operation, the defined data groups are permanently collected, evaluated and compared. Parameters for orientation are, for example, speed, vibration, temperature, pressure or power consumption.

Virtual machine assembly

Even before the Corona pandemic, IEF-Werner was working on digital processes, which received a real development boost during the pandemic. For example, virtual machine assembly using common communication solutions has found its way into daily business, but especially into international projects. The customer’s specialists come into play here and are instructed by IEF experts on how to assemble the plant. Via remote access, the IEF experts can connect at any time and support the specialists on site. On the one hand, this saves valuable resources that can be used to initiate and implement new projects elsewhere. On the other hand, it makes processes leaner, processing faster and implementation less wasteful.

In the future, the customer will be able to choose between the two installation variants, which will also be adapted to individual needs.

Further Information: www.ief.de