Success story

Peiseler: Flexible manufacturing in the Mobile Smart Factory

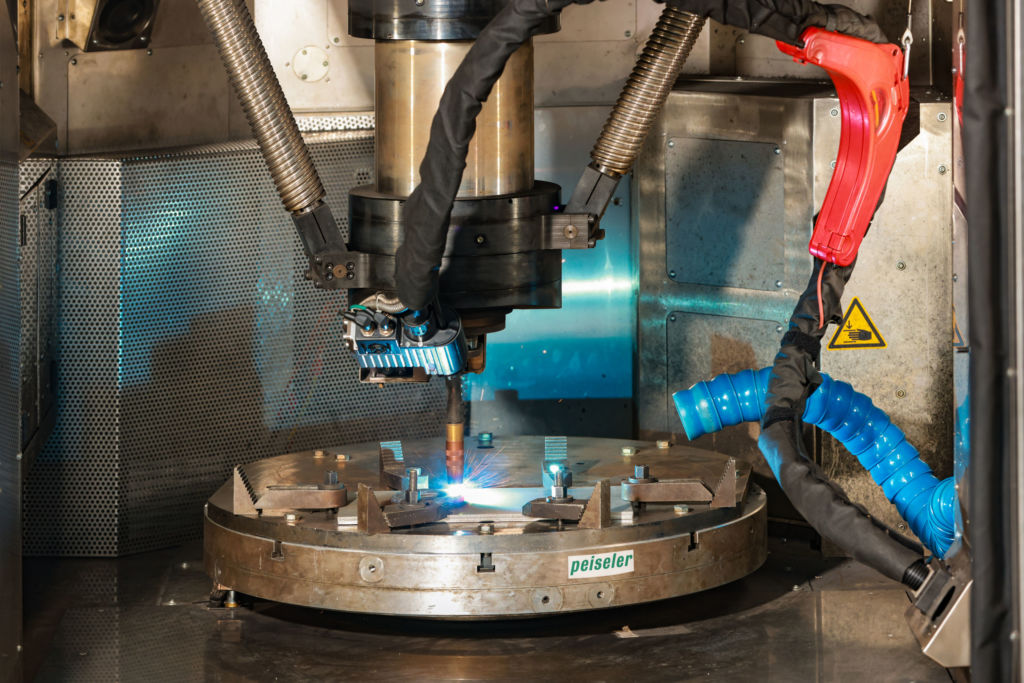

Manufacturing at any time at any place – the Mobile Smart Factory enables the production of necessary spare parts directly at the place of use. Precision machine builder Peiseler from Remscheid supplied crucial components for the mobile manufacturing project.

Mobile manufacturing in a container

When it comes to supplying spare parts for machines or systems, things usually have to move fast. Every minute counts, because production downtimes can cause immense costs. The solution: mobile production in two containers, developed by Bionic Production in cooperation with the Remscheid-based company Peiseler and its customer Metrom. Wherever infrastructure and logistics are difficult to develop and spare parts can only be procured with a long delay or at high cost, such as in the mining, shipping or rail sectors, the Mobile Smart Factory (MSF) provides a remedy. In a 20-foot container, components can be quickly repaired or manufactured from scratch using additive and subtractive manufacturing.

Mature cooling concept

Additive manufacturing is based on “Wire Arc Additive Manufacturing” (WAAM). This process is particularly suitable for small series or repairs. In WAAM, a metal wire melted with an electric arc is applied layer by layer to produce the metal component. The milling work required afterwards is carried out in the same system and thus in a single clamping operation – a novelty in the field, which means significant time savings. For the WAAM process, the Peiseler ATU 400 rotary table with special face plate and integrated cooling concept is used. The water-cooled face plate in particular offers decisive added value – after all, temperatures of around 4000 °C can occur during arc welding.

Future model

All components of the Mobile Smart Factory are designed to meet the stringent conditions of welding in confined spaces. This means that spare parts can be produced flexibly and downtimes significantly reduced. This is an advantage not only in terms of costs, but also in terms of sustainability, because long logistics routes for spare parts can be significantly reduced and large storage capacities are not necessary thanks to on-demand production. The Mobile Smart Factory therefore scores with flexibility and independence – a decisive competitive advantage these days!

Further Information: www.peiseler.de and www.mobile-smart-factory.com

Cover image: © Ulrich Perrey