Success story

BETEK – Successful internationalization

The carbide tool manufacturer BETEK’s Chinese production branch was awarded the “Rapid Growth Award” for its 300-percent sales growth in fiscal 2017. And in 2018, demand rose so rapidly that they started planning the next expansion.

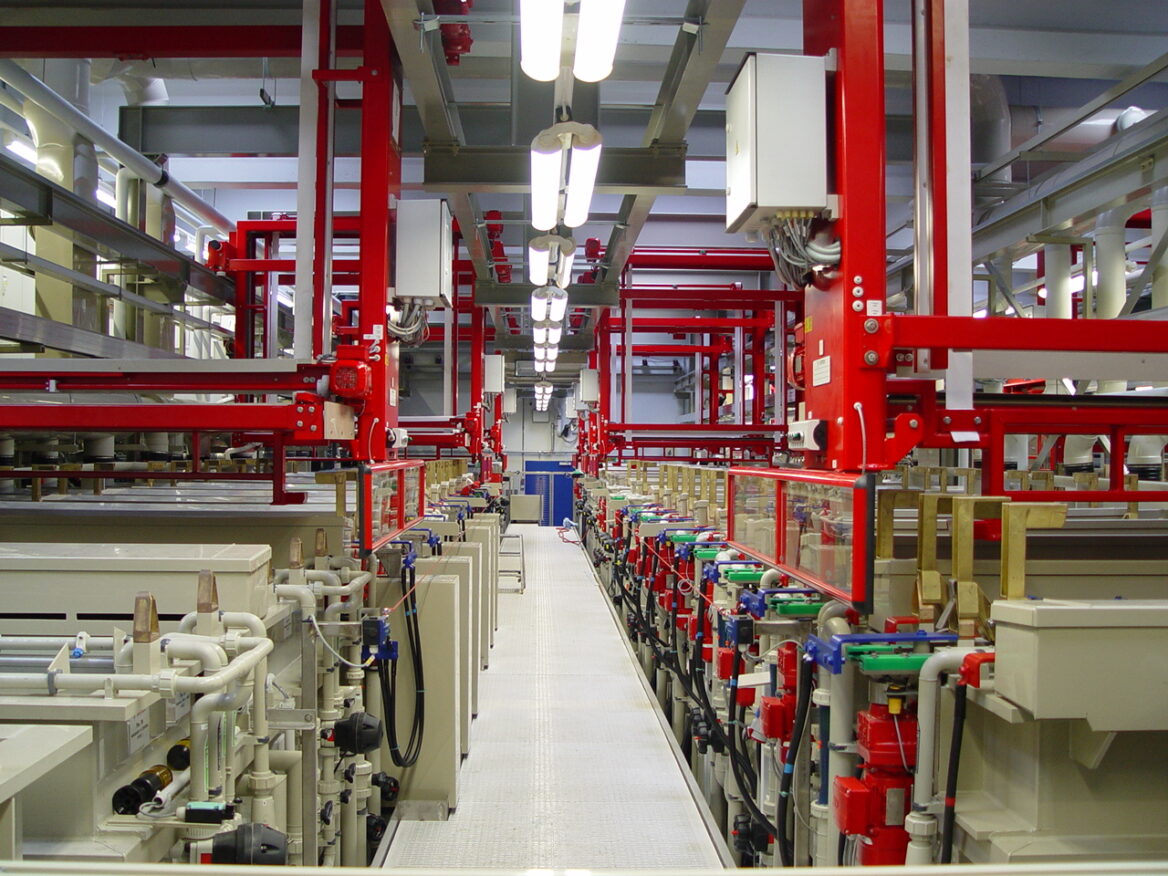

Order to set up a new production facility in China

In 2015, the managing directors of BETEK tasked Technical Manager Bernd Kopp with helping to set up production at the Chinese branch in Taicang. In addition to the local knowledge and good network that the Chinese Managing Director Hao Zhang brought to the project, the company wanted technical expertise directly from the company’s seat in Aichhalden to be included in the construction of the new production facility.

This was an interesting task that required more than a little courage from Bernd Kopp. The move also included adapting to an entirely new culture. But he made the decision, and a short while later set up his life 8,900 kilometers to the east.

After 15 months, production, storage and administration capacities were constructed on a 3,500 square meter site, and customers in Asia were partially supplied with locally manufactured products as early as 2016.

Surrounded by German companies

The environment and conditions for the new site were good. Taicang has a population of approximately 800,000 and is located directly on the banks of the Yangtze. Just a one-hour drive from the megacity of Shanghai, the town is home to more than 250 branches of German companies. BETEK Tools Taicang Ltd. is well connected here in a number of ways. The solid infrastructure also supports the further expansion of business contacts.

“Made in Germany” from China?

What surprised Bernd Kopp most at the beginning were customers’ reservations regarding quality: Made in Germany from China? How does that work? Easy: a strict quality control process in Germany. The Chinese production facility quickly drew almost level with the facility in Aichhalden. One particular strength of local production in fact is that they are perfectly suited to respond to the individual needs of the local customers.

There were also challenges involved, however. One of the greatest was managing the workforce. In addition to 35 permanent employees, the production facility also deployed temporary staff. However, despite contractual agreements, these workers simply did not turn up on several occasions. Building up a sense of loyalty to the company amongst employees therefore became an important task for management.

Customers value local contact

Today, German OEMs, such as Wirtgen and Bauer, and large Chinese manufacturers with great capacity requirements can place their orders at short notice. Many parts can be delivered after just 48 hours. And personal consultation is more or less “within walking distance.”

Because everything is running so well, Bernd Kopp has already been tasked with planning the next production facility. An expansion of the storage space is also planned. The third area of focus is on employee training. This is an important contributor to success as the two most important growth drivers at BETEK are service and quality.

If you were to ask Bernd Kopp if he made the right decision back then, the answer would be a resounding “Yes! Being involved with setting up the BETEK production facility in China has given me motivation and pride in spades.”

Further Information: www.betek.de